OUR EQUIPMENTS

Production Equipment Overview

-

Maximum Print Size: 1050 × 740 mm

-

Minimum Print Size: 520 × 360 mm

-

Country of Origin: Germany

-

Year of Manufacture: 2018

-

Key Advantages:

-

(1) Capable of printing on various materials with 8-color precision; delivers high-resolution output and sharp image quality.

-

(2) Supports 8-color printing in a single pass, significantly reducing production time.

-

(3) For full-color jobs, double-sided printing ensures vibrant colors with minimal color deviation.

-

-

-

Maximum Print Size: 750 × 540 mm

-

Minimum Print Size: 360 × 220 mm

-

Country of Origin: Japan

-

Year of Manufacture: 2013

-

Key Advantages:

-

(1) Delivers high color saturation and gloss for vivid, vibrant image output.

-

(2) Supports a wide range of substrates including paper, specialty paper, metallic cards (gold/silver), PVC, PET, and more.

-

(3) Integrated UV drying enables immediate curing during printing, reducing color shift and ensuring consistent high-quality results.

-

(4) Excellent resistance to optical distortion and abrasion for enhanced durability.

-

-

-

Maximum Print Size: 1020 × 720 mm

-

Minimum Print Size: 520 × 360 mm

-

Country of Origin: Japan

-

Year of Manufacture: 2019

-

Key Advantages:

-

(1) The first press in China equipped with seamless switching between conventional UV and H-UV systems.

-

(2) High-speed printing with compatibility across a wide range of substrates.

-

(3) Capable of delivering special surface finishes for premium packaging, including cosmetics.

-

(4) Eco-friendly operations implemented throughout the entire production process.

-

-

-

Country of Origin: Japan

-

Year of Manufacture: 2019

-

Key Advantages:

-

(1) Delivers sharp, stable halftone dot reproduction.

-

(2) Fast plate output speed ensures efficient prepress operations.

-

-

-

Country of Origin: China

-

Year of Manufacture: 2013

-

Key Advantages:

-

(1) Suitable for cutting various paper materials and plastic sheets.

-

(2) Delivers smooth, clean cutting surfaces.

-

-

YUANDONG TYMB-1100 Computer-Controlled Hot Stamping & Die-Cutting Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2022

3. Key Advantage:

• (1) Manual alignment enables precise and flexible sheet positioning with real-time adjustments.YISHENG YSM800 Fully Automatic Laminating Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2019

3. Key Advantages:

• (1) Maximum feeding size: 1100 × 1200 mm

• (2) Precision auto-alignment system effectively reduces material waste.

• (3) Accurate pressure control ensures tight and consistent film lamination.

• (4) Automatic dust removal system significantly minimizes surface contamination after lamination.FENGCHI FC-1310 Fully Automatic Mounting Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2019

3. Key Advantages:

• (1) Maximum feeding size: 1300 × 1000 mm

• (2) Maximum operating speed reaches 130 meters per minute, significantly boosting productivity.

• (3) Synchronized pressure bed ensures strong and precise bonding between top and bottom sheets.1. Country of Origin: China

2. Year of Manufacture: 2019

3. Key Advantages:

• (1) Maximum die-cutting area: 1040 × 730 mm

• (2) Maximum pressure of 300 tons ensures smooth, rounded edges on finished products.

• (3) Equipped with an automatic waste removal system, replacing manual cleanup and significantly improving efficiency and reducing material loss.

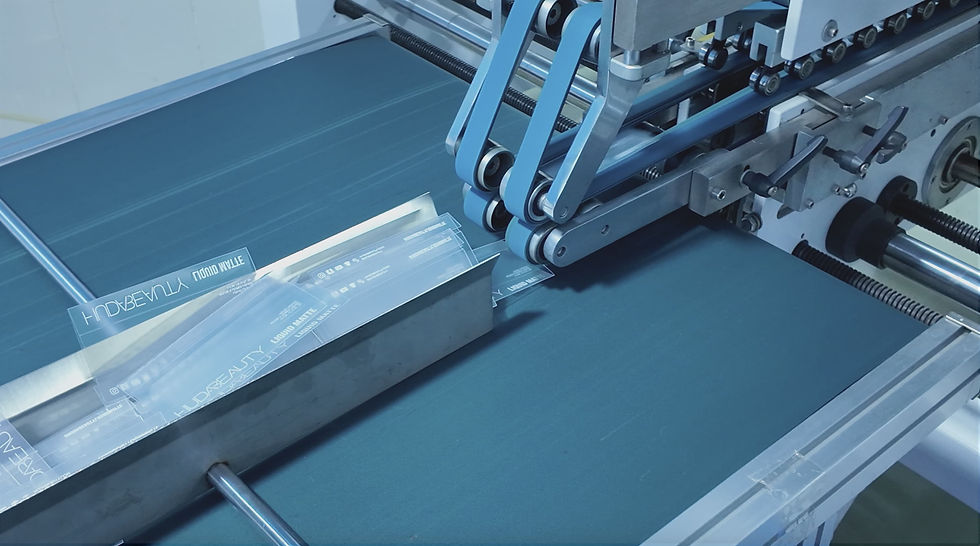

• (4) High-precision registration enables accurate alignment from all angles, resulting in cleaner, more refined packaging finishes.FENGMAI FM-1050P Fully Automatic Window Patching Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2019

3. Key Advantages:

• (1) High-precision alignment ensures clean and visually appealing window placement.

• (2) Stable glue control eliminates overflow issues — say goodbye to excess glue marks.YUELONG YL-980C4/C6 Fully Automatic Folder Gluer – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2019

3. Key Advantages:

• (1) Equipped with five mechanical arms, capable of producing various custom and irregular box types.

• (2) High-speed operation significantly boosts productivity.

• (3) Adjustable pressure bed ensures firm adhesion and a refined box appearance.GUOWANG C106Y Fully Automatic Hot Foil Stamping Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2022

3. Key Advantages:

• (1) Precision registration allows accurate multi-angle alignment for refined and visually appealing finishes.

• (2) Greatly enhances production efficiency to meet tight delivery schedules.TIANLIN Fully Automatic Plastic Box Gluing Machine – Equipment Overview

1. Country of Origin: China

2. Year of Manufacture: 2022

3. Key Advantages:

• (1) Equipped with automatic film blowing and cutting functions.

• (2) Imported glue tank ensures high stability with no stringing.

• (3) Large feeding section supports box sizes up to 1100 mm and as small as 50 mm.We operate a secure printing workshop to handle confidential or high-security packaging and printing projects.

-

Country of Origin: China

-

Year of Manufacture: 2021

-

Key Advantages:

(1) Combines positive and negative pressure for sharp, stable forming results.

(2) Fully automated workflow improves production speed and reduces manual labor.

(3) Compatible with multiple plastic materials including PET, PVC, PS, and PP.

-

Country of Origin: China

Year of Manufacture: 2020

Key Advantages:

(1) High-speed spindle ensures smooth, accurate engraving and milling performance.

(2) CNC control panel enables complex multi-axis machining with high repeatability.

(3) Fully enclosed design improves safety and reduces dust emission.

1. Country of Origin: China

2. Year of Manufacture: 2018

3. Key Advantages:(1) Uses vacuum suction to achieve fast and consistent plastic forming.

(2) Ideal for producing clear blister trays with stable shape and precision.

(3) Integrated heating and forming system ensures high production efficiency.

(4) Compatible with PET, PVC, PS, and other thermoplastic sheet materials.

-

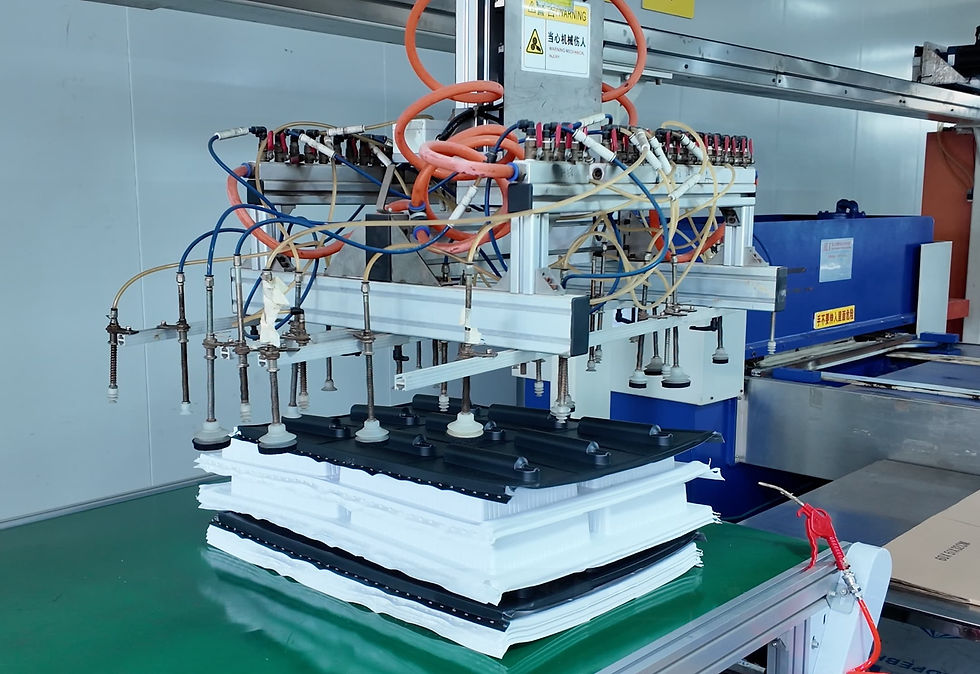

Country of Origin: China

-

Year of Manufacture: 2019

-

Key Advantages:

(1) Enables precise and repeatable movements for consistent handling and automation.

(2) Reduces manual labor and minimizes operational errors in repetitive tasks.

(3) Easily programmable for a wide range of applications such as loading, unloading.

-

01

KAB 8+1 UV Printing Press

-

Capable of printing on various materials with 8-color precision; delivers high-resolution output and sharp image quality.

-

Supports 8-color printing in a single pass, significantly reducing production time.

-

For full-color jobs, double-sided printing ensures vibrant colors with minimal color deviation.

02

KOMORI 6-Color UV Printing Press

-

Delivers high color saturation and gloss for vivid, vibrant image output.

-

Supports a wide range of substrates including paper, specialty paper, metallic cards (gold/silver), PVC, PET, and more.

-

Integrated UV drying enables immediate curing during printing, reducing color shift and ensuring consistent high-quality results.

-

Excellent resistance to optical distortion and abrasion for enhanced durability.

03

KOMORI 7+1 UV Printing Press

-

The first press in China equipped with seamless switching between conventional UV and H-UV systems.

-

High-speed printing with compatibility across a wide range of substrates.

-

Capable of delivering special surface finishes for premium packaging, including cosmetics.

-

Eco-friendly operations implemented throughout the entire production process.

04

Semi-Automatic Cutting Machine

-

Suitable for cutting various paper materials and plastic sheets.

-

Delivers smooth, clean cutting surfaces.

05

Hot Stamping & Die-Cutting Machine

• Manual alignment enables precise and flexible sheet positioning with real-time adjustments.

06

Fully Automatic Laminating Machine

• Maximum feeding size: 1100 × 1200 mm

• Precision auto-alignment system effectively reduces material waste.

• Accurate pressure control ensures tight and consistent film lamination.

• Automatic dust removal system significantly minimizes surface contamination after lamination.

07

Fully Automatic Mounting Machine

• Maximum feeding size: 1300 × 1000 mm

• Maximum operating speed reaches 130 meters per minute, significantly boosting productivity.

• Synchronized pressure bed ensures strong and precise bonding between top and bottom sheets.

08

Fully Automatic

Window Patching Machine

• High-precision alignment ensures clean and visually appealing window placement.

• Stable glue control eliminates overflow issues — say goodbye to excess glue marks.

09

Fully Automatic

Plastic Box Gluing Machine

• Equipped with automatic film blowing and cutting functions.

• Imported glue tank ensures high stability with no stringing.

• Large feeding section supports box sizes up to 1100 mm and as small as 50 mm.

10

Fully Automatic Box Folding Machine

• Equipped with five mechanical arms, capable of producing various custom and irregular box types.

• High-speed operation significantly boosts productivity.

• Adjustable pressure bed ensures firm adhesion and a refined box appearance.

11

Printing machine operating console

• Centralized interface for monitoring and adjusting print parameters in real time.

• Ensures precise color registration and alignment during high-speed printing.

• User-friendly layout improves operational efficiency and reduces training time.

• Supports integration with automated printing and inspection systems.

12

Automatic Positive and Negative

Pressure Forming Machine

• Combines positive and negative pressure for sharp, stable forming results.

• Fully automated workflow improves production speed and reduces manual labor.

• Compatible with multiple plastic materials including PET, PVC, PS, and PP.

13

Precision Engraving and Milling Machine

• High-speed spindle ensures smooth, accurate engraving and milling performance.

• CNC control panel enables complex multi-axis machining with high repeatability.

• Fully enclosed design improves safety and reduces dust emission.

14

Automatic Vacuum Forming Machine

• Uses vacuum suction to achieve fast and consistent plastic forming.

• Ideal for producing clear blister trays with stable shape and precision.

• Integrated heating and forming system ensures high production efficiency.

• Compatible with PET, PVC, PS, and other thermoplastic sheet materials.

15

Automatic Robotic Arm

• Enables precise and repeatable movements for consistent handling and automation.

• Reduces manual labor and minimizes operational errors in repetitive tasks.

• Easily programmable for a wide range of applications such as loading, unloading.